by: Anita Balachandra

Four weeks after delivering the State of the Union address to Congress, President Obama will announce that public-private partnerships will lead the Digital Manufacturing and Design Institute (DMDI) in Chicago and the Lightweight and Modern Materials Manufacturing Institute (LM3I) in the Detroit metro area. Both institutes are being sponsored by the Department of Defense. Each will receive $70M in federal funding over five years, matched by cash and in-kind funding from the two states, the city of Chicago, and participating companies. In 2013, DOD funded the first manufacturing institute, America Makes, which is focused on additive manufacturing and based in Youngstown, Ohio.

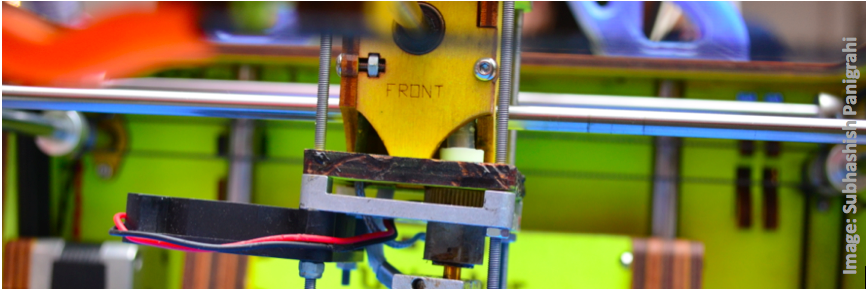

Taken together, the three DOD institutes address a critical opportunity for American manufacturing, namely, the adoption of new techniques that will increase cycle times, reduce costs, and enable the incorporation of new materials. The affordability of computing power now makes it possible to apply high-performance computing techniques to manufacturing processes, directing not only design, but the actual formation of unique parts. These three institutes each apply that computing power to different aspects of the manufacturing process.

The Chicago-based DMDI will be focused on developing, and incorporating electro-mechanical design and manufacturing capabilities so as to enable:

• Acceleration of product or process qualification,

• Incorporation of sensors and controls in components and systems, and

• Improvement of network security in collaborative manufacturing environments.

The Detroit-based LM3I will focus on integrated design and manufacturing of lightweight components and structures for commercial and defense applications, specifically:

• Demonstrating and scaling production of lightweight alloys,

• Accelerating design and integration of novel materials into new products,

• Improving manufacturing processes by increasing automation and reducing costs, and

• Developing these skills and expertise throughout the manufacturing workforce.

These goals speak directly to one of the greatest challenges facing American manufacturing today. World-class research in our universities is often developed and commercialized elsewhere precisely because of the cost and complexity of moving from lab to prototype to commercial production scale.

Public-private partnerships assemble and deploy resources and expertise in shared platforms to distribute the costs and the risks of experimenting, demonstrating, verifying and qualifying new products and processes. Moreover, these institutes will also provide a vehicle for organizing the supply chain. Perhaps most importantly, these institutes will provide smaller suppliers access to equipment and expertise they couldn’t afford on their own. “The Department of Defense, which depends on the domestic industrial base, has historically played a critical role in ensuring that in addition to discovering new technologies, we have the manufacturing expertise and capacity to develop, refine and produce them,” said TechVision21’s Kelly Carnes, “Today’s announcement is a laudable and necessary continuation of that role.”

Read what Mark Muro, senior fellow and director of policy for the Metropolitan Policy Program at Brookings, wrote on the subject of manufacturing hubs here http://www.brookings.edu/blogs/up-front/posts/2013/02/13-state-of-the-union-manufacturing-hubs-muro-fikri

Image: Subhashish Panigrahi / Wikimedia Commons CC-BY-SA 3.0 https://commons.wikimedia.org/wiki/User:Psubhashish